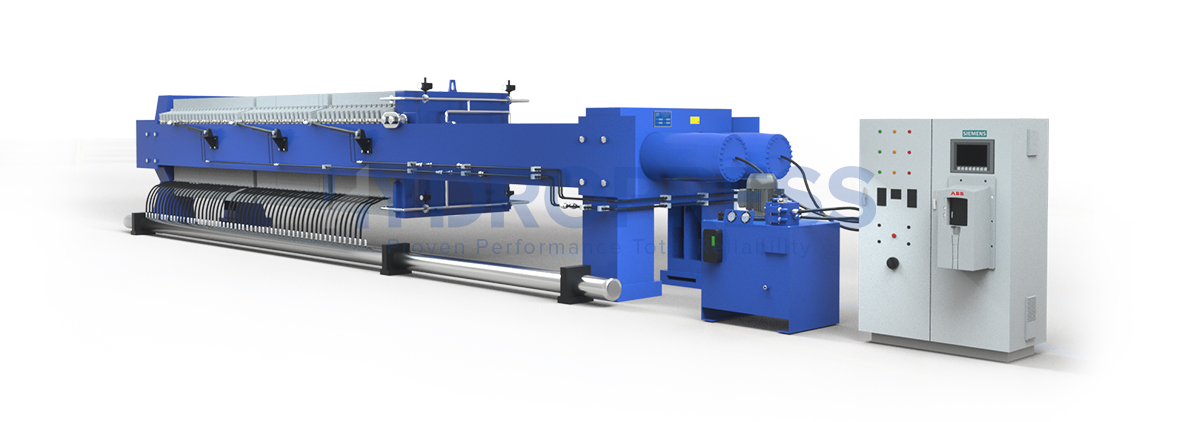

Membrane Filter Presses are used for extra moisture reduction in the cake. Our company is a celebrated name offering excellent industrial membrane filter press to many established industries across India.

We also export high pressure membrane filter press to several clients across the world. Our company manufactures membrane filter press according to international standards and quality. The membrane squeeze plate is offered to suit up to 16 bar squeezing pressure. Due to additional liquid extraction during the squeeze cycle, a solid percentage increases.

Filtration cycle time are reduced compared to the conventional recess chamber plate (Plate and Frame) filter press, resulting in benefits of membrane plates v/s chamber plates. Conventional type filter presses are limited to use feed pump discharge pressure to produce dry solids, resulting in longer cycle times.

The membrane filter press offered by us is gaining widespread recognition as it reduces disposal costs for filter presses. It also reduces the moisture content, thus making it ideal for new plants.

The offered product is designed to dewater the most difficult sludge and to protect the plates against potential cake less chambers.

The membrane squeeze plate is offered to suit up to 16 bar squeezing pressure. Due to additional liquid extraction during the squeeze cycle, a solid percentage increases. Filtration cycle time is reduced compared to the conventional recess chamber plate (Plate and Frame) filter press, resulting in benefits of membrane plates v/s chamber plates.

We have developed high pressure membrane filter press in order to carry out difficult filtration processes with ease. Extreme squeeze pressure is possible due to the combination of the special feed inlet design and selected special materials.

The membrane squeeze plate reduces the long packing cycle by introducing a squeeze medium into the center of the membrane squeeze plate. This allows the membranes to flex against the cake, compressing and packing it. Filtration cycles get shorter and dry solids are increased thereby reducing waste volume.

SPECIFICATIONS

- Shorter cycle time

- Welded membrane plates

- Increased dry solids

- Reduced filtration time

- Easily replaceable

- Membrane are common and can be used on either side of the plate

- Pip style drainage surface design for uniform flex

- Reduced cake washing time

- Lesser wash water consumption

- Increased capacity

- Lower waste disposal cost

- Lower operating cost

- Excellent cake discharge

- Higher quality and valued end product

- Plate size ranging from 630 x 630 mm to 2000 X 2000mm

- Membrane: PP/EP-40

- Corner-Feed for Better Filtration

- Pressure: Upto 24 bar

- Controls: Fully Automatic/Manual

- Hydraulics: Upto 500 tons

- Complete Automatic cycle option

- Various different configurations

The membrane squeeze plate reduces the long packing cycle by introducing a squeeze medium into the center of the membrane squeeze plate. This allows the membranes to flex against the cake, compressing and packing it.

Filtration cycles get shorter and dry solids are increased thereby reducing waste volume. Membrane filter press is designed to dewater the most difficult sludge and to protect the plates against potential cake less chambers. We have developed high pressure membranes filter press in order to carry out difficult filtration processes with ease.

Extreme squeeze pressure is possible due to the combination of the special feed inlet design and selected special materials. Our company manufactures and exports membrane filter press which comes with following features: Membrane filter presses are available in both automatic and semi automatic versions.

Improved Cake Washing:

Our membrane filter press improves cake washing by initiating a low-pressure pre-squeeze before the wash cycle begins. This pre-squeeze eliminates channelling (cracks and less well-formed areas of the cake) and produces a uniform, homogeneous filter cake, and optimum wash efficiency.

Highest Cake Solids:

By applying a high pressure squeeze to the filter cake, one can produce the final cake with solids content from 50 to 100% greater than can be achieved with conventional filter presses. This is important for both maximum yield where a high value liquid is your product and high solids-content, where reduced moisture content in the final cake is critical.

Our Membrane Filter Press provides a dryer cake that can be obtained using high feed pumping pressure in a conventional filter press. It significantly reduces or eliminates downstream thermal drying and associated costs in energy and time.

Corner-Feed for Better Filtration:

We recommend corner-feed plates because of their numerous design advantages for virtually every filter press installation. Our designing team incorporates these features in our membrane filter presses as well as in our conventional filter presses.

Corner-feed design offers efficient cake formation and provides even solids distribution through-out the plate stack. More importantly, eliminating a centre-feed eye allows construction of a stronger plate requiring no supporting stay bosses which hamper thorough cake washing and cake discharge.

With a center-feed filter plate, cake washing is difficult due to wash water "short circuiting" through the open center-feed eye. Corner-feed is the only plate design which assures thorough cake washing integrity.

APPLICATIONS

Best for dry fractionation of palmolein, ETP-plants, granites, marble & ceramic industries, gypsum, bentoite, crystalline salts, pigments, dry precipitates, sludges generated from galvanizing plants containing chromium, zinc, aluminium, copper, nickel or cadmium, etc.